PRODUCTS

Chip Solder

Manufactured to the same specifications as common SMT chip materials, it overcomes the limitations of stencil masks and is widely used in tasks that require extremely precise quantities.

It is also used in large quantities to replace wave, selective and robotic soldering or to automate hand soldering processes.

Soldering Test

Soldering Test

Connector application video Military products and automotive electronic products

Connector application video Military products and automotive electronic products

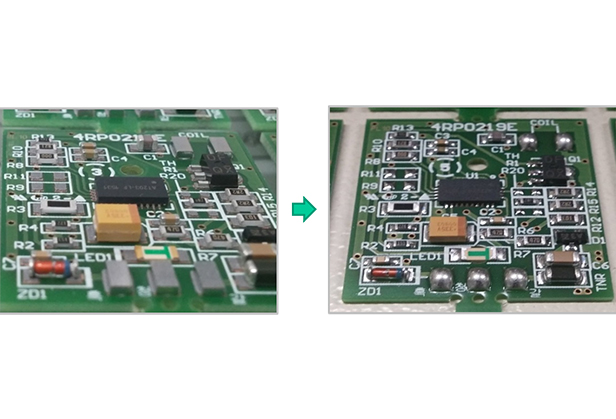

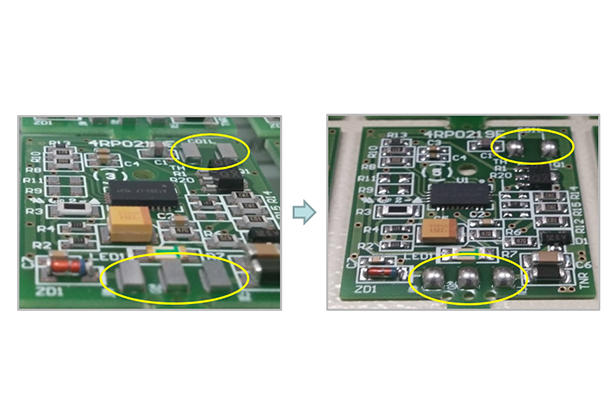

Car headlight LED soldering amount comparison (1005, 1608)

Car headlight LED soldering amount comparison (0603)

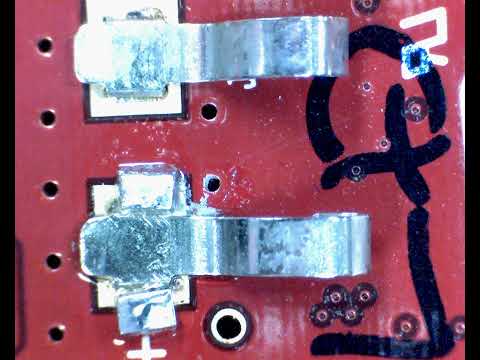

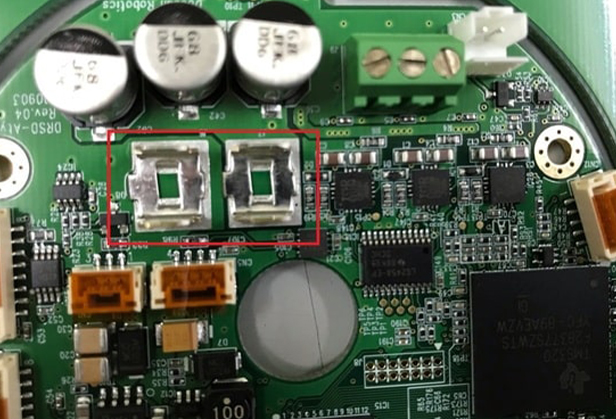

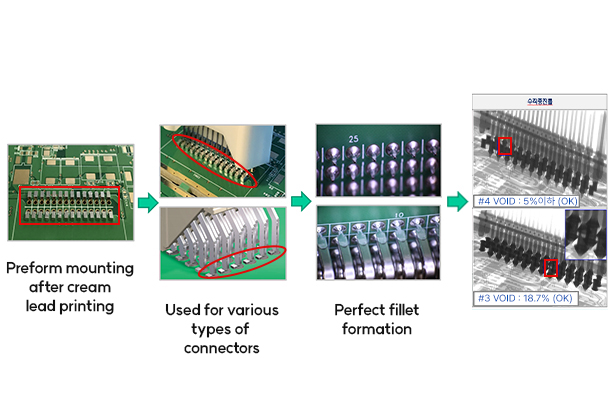

Car block box power terminal

This is a case where the 1608 preform was used for the power terminal of the car black box to solve the defect. In the case of metal press products such as various connectors, USB terminals, ear jacks, shield cases, and power jacks, there is a lifting phenomenon due to bending of the leads basically. Complete soldering is difficult with the amount of solder in mask printing.

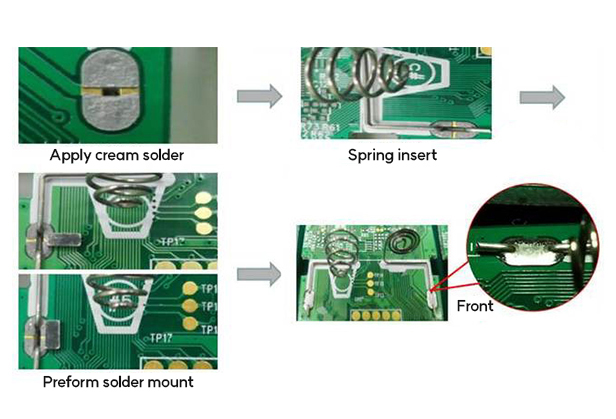

Remote control power terminal spring

By applying 3216 preform to the remote control spring soldering process, which is a typical manual process, it helped to reduce labor costs and improve productivity by automating manual work.

Robot joint power terminal application

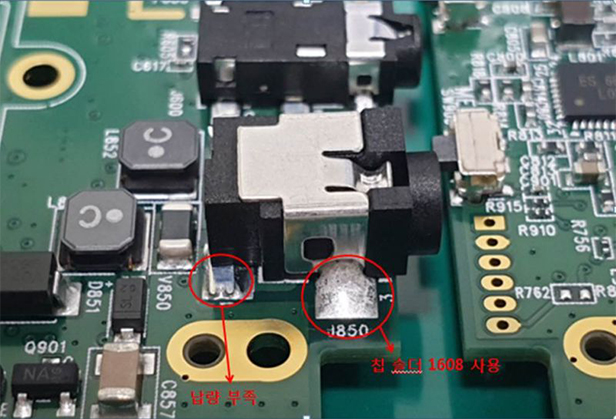

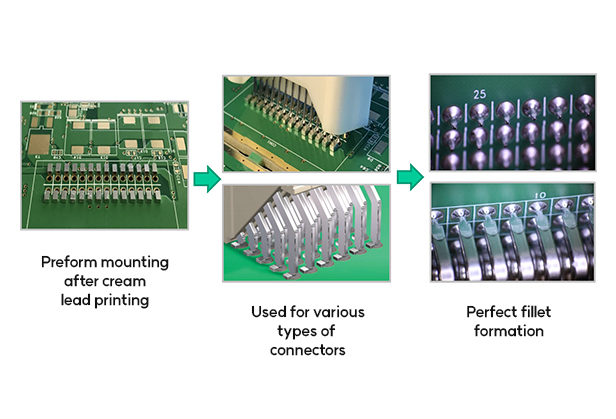

Insert Type Connector

SMT Type Connector (Inverter)

It is widely used in parts and appliances that receive strong force or frequently come into contact, as well as parts and products that require dropping or extreme reliability tests.

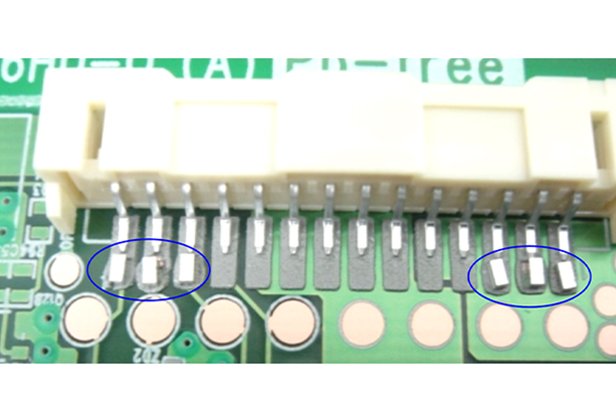

Application of additional lead for signal line (proximity sensor)

Additional soldering work for proximity sensor wiring and coil soldering is replaced with preform solder instead of existing solder, thereby maintaining a constant amount of solder and suppressing operator interference as much as possible, thereby improving consistent quality and productivity.

Waveless Type Connector

Proximity sensor signal line

After replacing real solder with preform solder for the additional soldering work for wiring and coil soldering of proximity sensors, quality and productivity are improved by maintaining a constant amount of solder and suppressing operator interference.

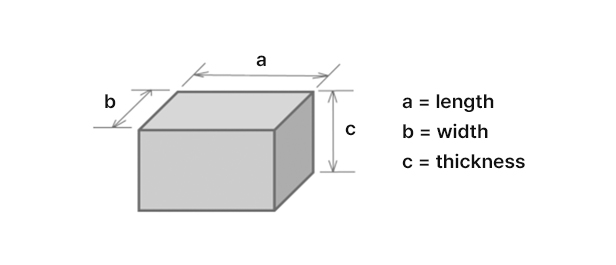

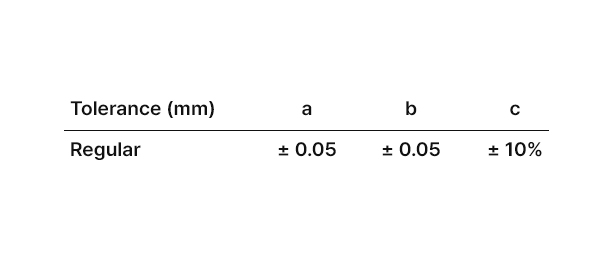

Size

| Division | Size | Dimensions | Volume | |||

|---|---|---|---|---|---|---|

| a | b | c | ||||

| inch | mm | mm | mm3 | |||

| Micro Size | 01005L | 0402L | 0.40 | 0.15 | 0.076 | 0.0046 |

| 01005H | 0402H | 0.40 | 0.20 | 0.10 | 0.0080 | |

| 01005 | 0402 | 0.40 | 0.20 | 0.16 | 0.0128 | |

| 0201S | 044028 | 0.44 | 0.28 | 0.28 | 0.0345 | |

| 0201 | 0503 | 0.47 | 0.28 | 0.28 | 0.0368 | |

| 0201H | 0503H | 0.51 | 0.25 | 0.10 | 0.0130 | |

| 0202 | 0505 | 0.51 | 0.51 | 0.25 | 0.0319 | |

| 0603 | 0.60 | 0.30 | 0.30 | 0.0540 | ||

| 0402L | 1005L | 1.0 | 0.5 | 0.13 | 0.0650 | |

| 0402H | 1006H | 1.0 | 0.6 | 0.25 | 0.1500 | |

| 0402 | 1005 | 1.0 | 0.5 | 0.5 | 0.2500 | |

| Middle Size | 0603H | 1608H | 1.6 | 0.8 | 0.5 | 0.0640 |

| 0603 | 1608 | 1.6 | 0.8 | 0.8 | 1.0240 | |

| 2012 | 2.0 | 1.2 | 0.8 | 1.9200 | ||

| Large Size | 0805H | 2013H | 2.01 | 1.3 | 0.4 | 1.0452 |

| 0805 | 2013 | 2.01 | 1.3 | 0.76 | 1.9859 | |

| 3216 | 3.2 | 1.6 | 0.8 | 4.0960 | ||

Alloy

| Sn | Ag | Cu | Bi | Pb | Melting P. | ||

|---|---|---|---|---|---|---|---|

| Lead - Free | SAC305 | 96.5 | 3.0 | 0.5 | - | - | 217 - 219 |

| Sn96.5Ag3.5 | 96.5 | 3.5 | - | - | - | 217 | |

| SACX(SAC0807) | 98.5 | 0.8 | 0.7 | - | - | 217 - 228 | |

| SACX(SAC0307) | 99.0 | 0.3 | 0.7 | - | - | 219 - 229 | |

| SAC357 | 95.8 | 3.5 | 0.7 | - | - | 217 | |

| SAC387 | 95.5 | 3.8 | 0.7 | - | - | 217 | |

| SAC405 | 95.5 | 4.0 | 0.5 | - | - | 217 - 218 | |

| Low - T | SnBi57.6Ag0.4 | 42 | 0.4 | - | 57.6 | - | 138 |

| Tin - Lead | Sn63PB37 | 63.0 | - | - | - | 37.0 | 183 |

| Sb62Pb36Ag2 | 62.0 | 2.0 | - | - | 36.0 | 179 - 182 | |

| Sn62.8Pb36.8Ag0.4 | 62.0 | 0.4 | - | - | 36.8 | 179 - 183 |